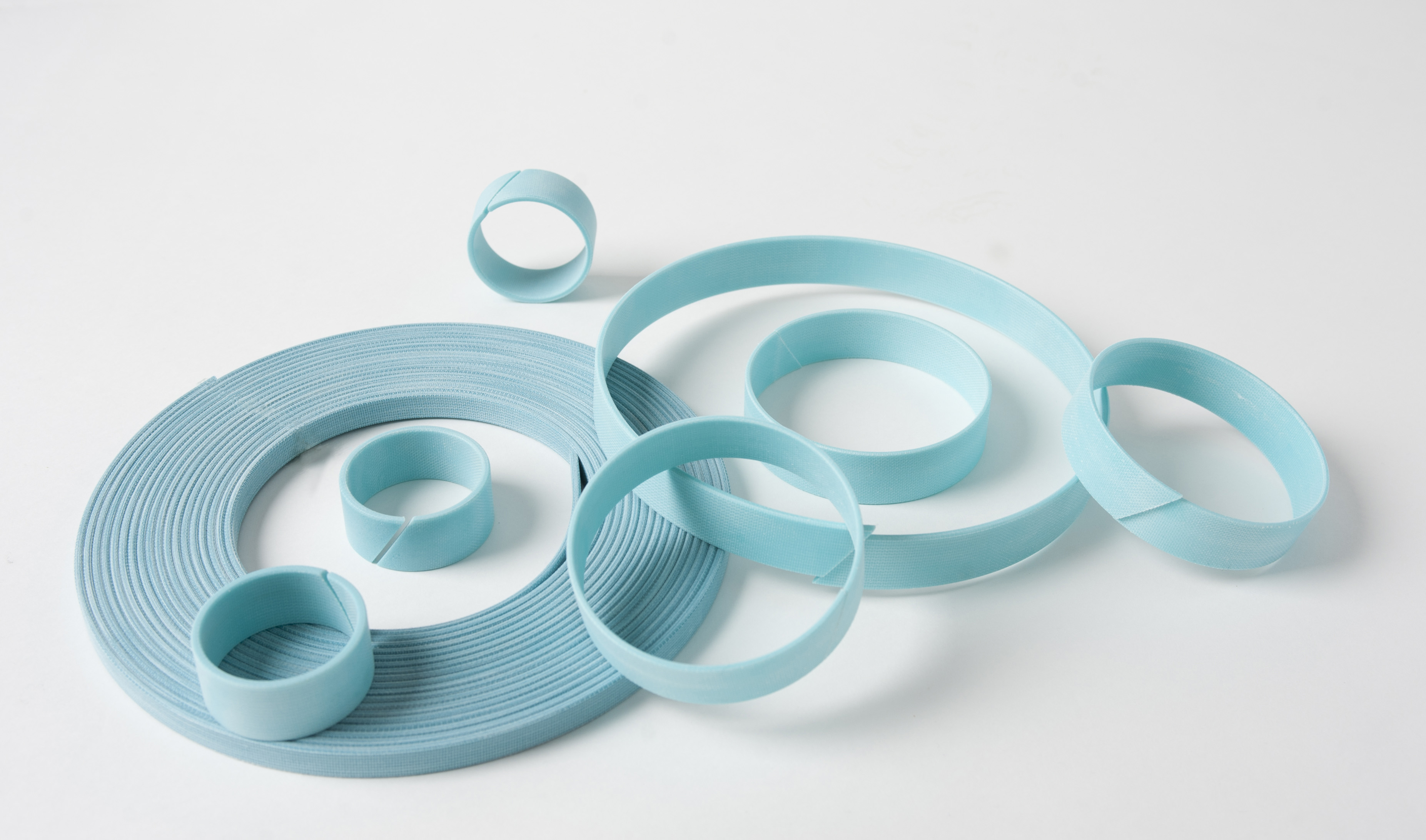

In high-performance hydraulic and pneumatic systems, wear rings play a crucial role in ensuring longevity, efficiency, and cost control. By preventing metal-to-metal contact, maintaining alignment, and protecting cylinders from costly damage, the right wear ring material can enhance load capacity, reduce friction, and keep your system running smoothly, even in the most demanding conditions. This choice often means the difference between frequent maintenance and extended equipment life.

Some wear rings excel under heavy pressure, while others resist contaminants or maintain dimensional stability amid temperature and humidity changes. From cost-effective nylon composites to chemically resistant, high-load polyester resins, understanding the unique strengths of each material is essential for optimizing your equipment’s performance and durability.

UNDERSTANDING C40 VS. GN40

C40 - Polyester Resin Composite Wear Ring

C40 wear rings are engineered from a premium-grade polyester resin, also known as Polycot, reinforced with synthetic fiber cloth and enhanced with PTFE micro-powder to provide built-in dry lubrication. This composite construction delivers exceptional mechanical and chemical performance in demanding hydraulic environments.

Key Features:

- High Compressive Strength: Built to handle substantial mechanical loads with a compressive strength of 50,000 PSI (345 MPa), ensuring extended service life and superior durability.

- Non-Hygroscopic: Resistant to moisture absorption, maintaining dimensional stability even in humid or wet conditions.

- Excellent Temperature & Chemical Resistance: Operates reliably in a broad temperature range from -40°F to 275°F and remains compatible with a wide variety of hydraulic fluids, oils, and chemicals.

LIMITATIONS:

- Contaminant Sensitivity: While highly durable, C40 wear rings can experience increased wear or scratching if contaminants such as dirt or metal particles enter the sealing environment.

- Premium Price Point: Higher upfront price due to its premium materials and superior performance characteristics.

GN40 – Glass-Filled Nylon Wear Ring

GN40 wear rings are made from a nylon base reinforced with 40% glass fibers, enhancing their strength, dimensional stability, and resistance to wear. These wear rings are ideal for applications demanding high load capacity and low friction performance.

KEY FEATURES:

- Cost-effective: Typically more affordable than C40 wear rings, making them a budget-friendly option.

- Contaminant-resistant: Capable of ingesting contaminants such as dirt and metal particles, reducing the risk of scratching or damaging hardware surfaces.

- High-wear Resistance: Designed to endure high-friction conditions, extending service life.

- Low Coefficient of Friction: Promotes smooth operation with reduced energy loss and minimal wear over time, even under dynamic loads.

- High Tensile Strength: Maintains structural integrity in demanding environments, supporting up to 29,000 PSI (200 MPa).

LIMITATIONS:

- Moisture Absorption: Prone to hygroscopic growth, which can lead to dimensional changes in humid environments.

- Limited Chemical Resistance: Less suitable for applications involving aggressive chemicals, oils, or solvents.

FIND THE WEAR RING THAT MATCHES YOUR APPLICATION

Both GN40 and C40 wear rings are widely used in standard hydraulic sealing applications, offering dependable protection and smooth operation. GN40 wear rings are valued for their cost-effectiveness, contaminant resistance, and solid performance under typical loads. On the other hand, C40 wear rings are engineered for more demanding environments, featuring high compressive strength (up to 50,000 PSI), excellent chemical and temperature resistance, and dimensional stability due to their non-hygroscopic properties. While C40 wear rings carry a higher upfront cost and can be more sensitive to contaminants, their durability and ability to withstand extreme loads make them a preferable choice for heavy-duty cylinders and harsher conditions. Understanding the demands of your specific application will help you select the wear ring that delivers the right balance of durability and performance.

precision you can count on

All Black Hawk wear rings are manufactured to tight tolerances, consistently meeting a ±0.001” cross-sectional accuracy. Unlike net-molded wear rings, which are prone to dog-boning—a deformation that can cause breakage and shorten product life—our rings are engineered for maximum consistency and performance.

why choose black hawk seals?

At Black Hawk Seals, we recognize that selecting the right wear ring material is critical to your system’s performance and longevity. That’s why we offer both C40 and GN40 wear ring options—delivering high-quality, application-specific solutions designed to meet your exact needs. Our wear rings and sealing products are manufactured to the highest standards, ensuring durability, reliability, and optimal sealing performance in the most demanding environments.

What You Can Expect from Black Hawk Seals:

- Premium-Grade Materials

- We utilize top-tier materials, including GN40 glass-filled nylon and C40 polyester resin composite, to deliver superior strength, wear resistance, and long-lasting sealing performance.

- Industry Expertise

- Our knowledgeable team is here to help you identify the proper seal for your specific application.

- Fast Shipping & Competitive Pricing

- Get the seals you need, when you need them, and at a price that works with your budget.

- Custom Solutions

- Require a unique size or material formulation? We specialize in custom-engineered solutions tailored to your application.