From mining and aggregates to construction and forestry, tough machinery has to face challenges of all kinds including dirt, mud, and many corrosive elements that can be harsh on equipment and cause failure when not protected. Our new line of Dual-Face Seals is here to give the advantage back to the machines. This new product in our line of mechanical seals is designed to safeguard equipment parts from dust, dirt, water, and other contaminants, offering long-lasting durability in harsh environments.

The zero-tolerance face protects your machine from harsh contaminants and keeps you running and on track for your production goals. The best part is that you don't have to wait a year to get them, we're making sure you can get your Dual-Face Seals faster than ever with our advanced logistics providing a short lead time. Let's learn more about Dual-Face Seals and how you can order yours today.

Purpose and Application

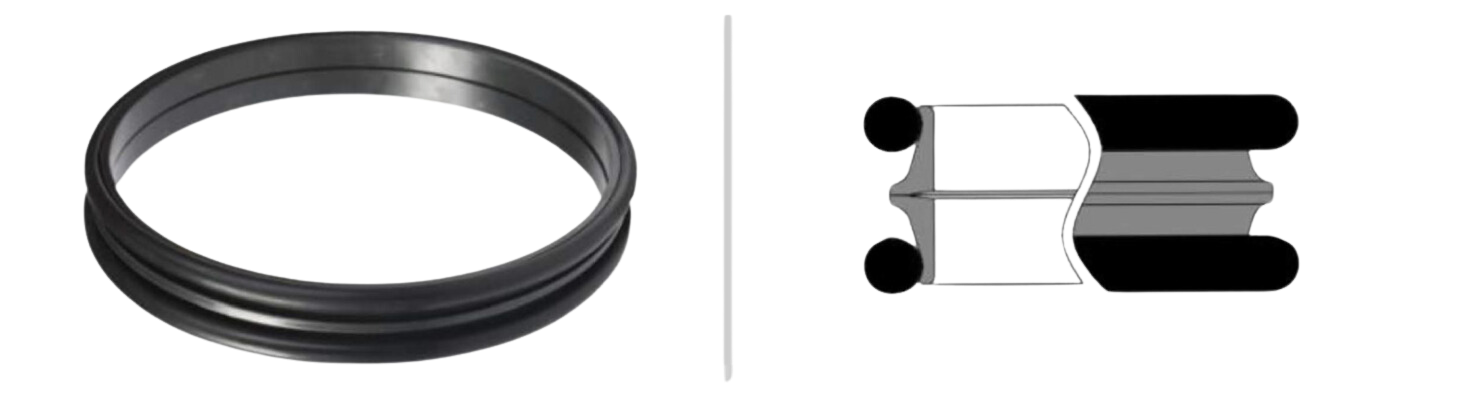

Dual-Face Seals, also known as mechanical face seals, provide an impermeable barrier between moving parts. Their design minimizes wear and tear in high-pressure, abrasive environments. Two separate floating metallic seals and two elastomeric load rings. As O-rings transfer pressure from the housing to seal rings, it allows one metal seal ring to rotate with the housing while the other remains stable. Seal rings interact with each other to form a contact sealing face perpendicular to the axis. As wear occurs, the contact band will move inwards. However, the O-ring releases elastic compensation, keeping the Dual-Face Seal in a precise position to maintain its stability.

These seals are vital in industries with extreme conditions such as construction, mining, and heavy machinery, where equipment reliability and longevity are critical. Typical applications include:

- Excavators

- Bulldozers

- Heavy-duty trucks

- Scraper conveyors

- Mixing machines

All of our Dual-Face Seals are manufactured in one location, ensuring quality throughout the entire process so you receive exactly what you ordered, every time. We can even provide an installation tool to make installation a breeze and get you back up and running in no time.

Advantages of Dual-Face Seals

- Enhanced Durability: With their robust construction, Dual-Face Seals significantly reduce friction and wear, extending the lifespan of machinery.

- Resistance to Harsh Conditions: These seals are engineered to withstand high temperatures, abrasive particles, and corrosive materials.

- Low Maintenance: Their self-lubricating properties lead to fewer service requirements, ensuring operational efficiency.

- Cost Efficiency: By preventing early damage to machinery components, Dual-Face Seals help reduce overall maintenance costs and downtime.

Why Choose Black Hawk Seals?

At Black Hawk Seals, we precision-engineer to deliver the highest performance. With a focus on superior material quality and innovative design, our seals offer unmatched reliability in even the toughest environments. By choosing Black Hawk Seals, you benefit from top-notch quality assurance, customization options for unique industrial needs, and expert support and consultation. We work directly with our distributors to ensure the right seal is going on the right application every time.

Ready to upgrade your machinery with dependable protection? Trust Black Hawk Seals for the ultimate in sealing technology. Explore our range of Dual-Face Seals today and keep your equipment running smoothly!