Seals play a critical role in preventing leakage, contamination, and ensuring optimal performance of a system. Understanding the different types and materials can lead to improved performance and cost-effectiveness. Whether you're dealing with hydraulic systems, pneumatic cylinders, or industrial machinery, the right seal can make all the difference in efficiency and longevity.

Black Hawk Seals’ line of high-performance and affordable seals could be the alternative you’ve been looking for to improve your system. Let’s dive into our seal offerings and the solutions they could provide.

What is a Piston Seal?

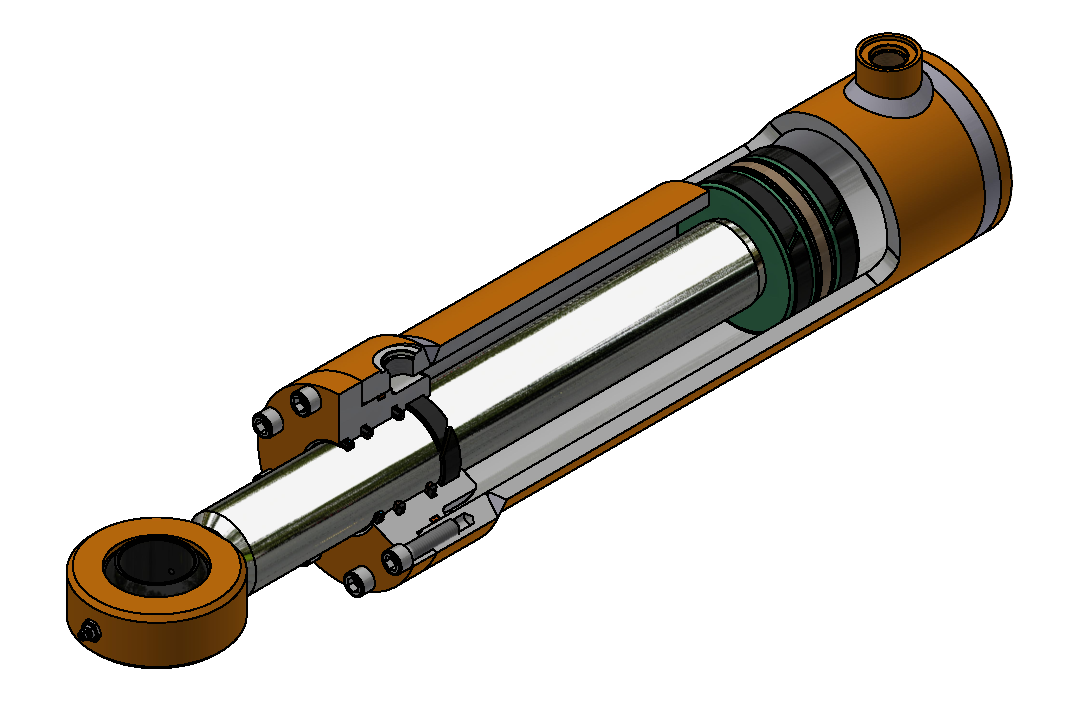

Piston seals are a vital component in hydraulic and pneumatic cylinders. These seals are designed to prevent fluid from bypassing the piston as it moves within the cylinder bore. These seals play a critical role in ensuring efficient operation and prolonging the lifespan of your equipment. Piston seals come in various types, including single-acting and double-acting seals, each suited for specific applications.

At Black Hawk Seals, we offer a range of high-quality Piston Seals crafted from durable materials such as polyurethane, nitrile rubber, and PTFE. Our seals are engineered to withstand high pressures, ensuring reliable performance even in the most demanding environments.

What is a Rod Seal?

Rod Seals are used for preventing fluid leakage from the cylinder to the outside environment. They work in tandem with Piston Seals to maintain the integrity of the system. Rod Seals are often exposed to abrasive conditions, making material selection essential for longevity.

Our Rod Seals at Black Hawk are designed to excel in challenging environments. Made from materials like urethane, nitrile rubber, fluorocarbon, and filled PTFE, these seals provide exceptional resistance to wear and abrasion. Whether you're dealing with heavy machinery or precision equipment, our Rod Seals deliver consistent performance.

What is a Static Seal?

Used to seal non-moving parts of a system, such as flanges, valves, or joints, Static Seals are crucial for maintaining system integrity. Unlike dynamic seals, Static Seals do not experience movement, but they must still provide a reliable barrier against leaks.

Black Hawk's Static Seals are manufactured using high-grade materials like thermoplastic polyurethanes. These materials are selected for their excellent chemical resistance and sealing properties, ensuring a tight and durable seal for your applications.

What is a Buffer Seal?

Last but not least, Buffer Seals are often employed in hydraulic systems to protect primary sealing elements from pressure spikes and contaminants. These seals act as a buffer, absorbing pressure fluctuations and preventing damage to the primary seals by acting as a barrier.

Our Buffer Seals are crafted with precision and care, using materials such as filled PTFE, urethane, and nylon. They are designed to extend the life of your primary seals and maintain system efficiency even in harsh operating conditions.

Why Choose Black Hawk Seals?

At Black Hawk Seals, we understand the importance of selecting the right sealing solution for your specific application. Our extensive product line offers a wide range of seals, including piston seals, rod seals, static seals, and buffer seals, available in various materials to meet your unique requirements.

- Performance: Our seals are engineered to meet the highest industry standards, ensuring optimal performance and reliability.

- Durability: Using premium materials, our seals are built to withstand the toughest conditions, reducing downtime and maintenance costs.

- Affordability: While maintaining exceptional quality, we offer competitive pricing to make our seals accessible to businesses of all sizes.

Don't settle for subpar sealing products that hinder your equipment's efficiency and lead to costly downtime. Black Hawk Seals offers a more cost-effective alternative, ensuring the same level of performance as premium sealing solutions.

Upgrade your sealing system with our comprehensive range of products, engineered to meet the highest industry standards. Contact us today to learn more about how our sealing solutions can optimize your operations while providing exceptional value for your investment.